Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

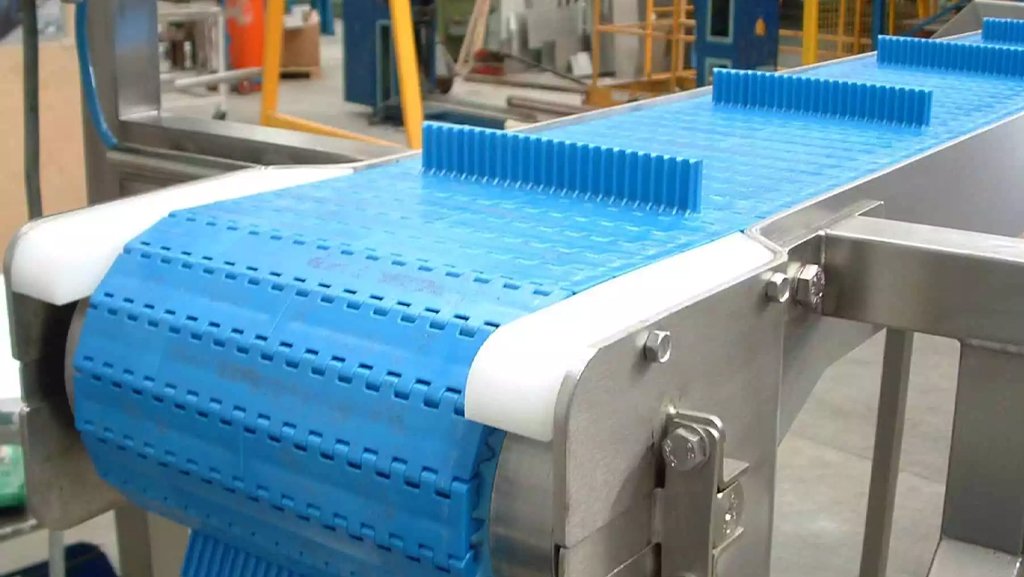

Active roller belts are innovative and ground breaking products that can help a business to streamline its operations by increasing throughput and efficiency, while simultaneously reducing footprint and total system costs. Active roller belts are employed in some 7,500 conveyors around the globe, delivering high performance conveyance across a huge range of different industries and sectors. In this post, we take a look at how the technology could help your business, read on for more information.

Advanced Performance and Increased Throughput

Computer aided design is used to help tailor every active roller belt solution to the exact requirements of an operation. Unique digital simulations are created and refined to identify the safest and most efficient route between two points. This is a factor that can greatly increase efficiency of traffic, optimising throughput, productivity and, ultimately, profitability.

Simplified Controls

Despite the advanced nature of ARB enabled products, the conveyance solutions feature simplified controls. This is an extremely important factor that ensures the systems provide an exemplary user experience.

Range of Solutions

ARB solutions are extremely versatile systems, able to deliver a range of diverse functions. The adaptable solutions, therefore, can replace multiple other conveyors at one time, a factor that helps to not only reduce the complexity of a system but dramatically cut footprint as well. Active roller belt enable products include: 90 degree transfers, aligners, switchers, turner dividers, mergers and sortation systems.

About Wrightfield

We are an experienced engineering company with more than 20 years working in the industry. We have particular expertise in the food processing and manufacturing sectors, specifically in the design, manufacture and installation of conveyor systems – including active roller belt enabled solutions.

Activated Roller Belt Equipped Conveyance Solutions (ARBE) are conveyor systems that use the Activated Roller Belt technology in order to provide efficient and precise movement of items. These systems are typically used in manufacturing and logistics environments, where they can be used for sorting, merging, and aligning items. Some features that ARBE conveyors may include are:

- Motorized rollers within the belt, which can be controlled independently to guide and control movement of items

- Sensors and control systems to detect and track items on the conveyor

- Integration with other equipment and systems, such as barcode scanners or robotics, to automate sorting and tracking processes.

- High-performance and durability in high traffic areas.

- Inclined or decline conveyors

- Curve conveyors

- The ability to handle a wide range of products, from small items to large and heavy loads.

Active Roller Belts – Find Out More

Click on the following link if you would like to find out more about active roller belts, or this link for information on other stainless steel equipment manufactured by Wrightfield.