Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

They say that a business runs on efficiency; however, when it comes to the food processing sector, businesses, quite literally, run on belt conveyors. These components are integral to any food processing operation and ensure that products are transported reliably and safely throughout a facility. At Wrightfield, we offer a full range of conveyors, ensuring you are able to find you perfect fit.

Wrightfield Belt Conveyors

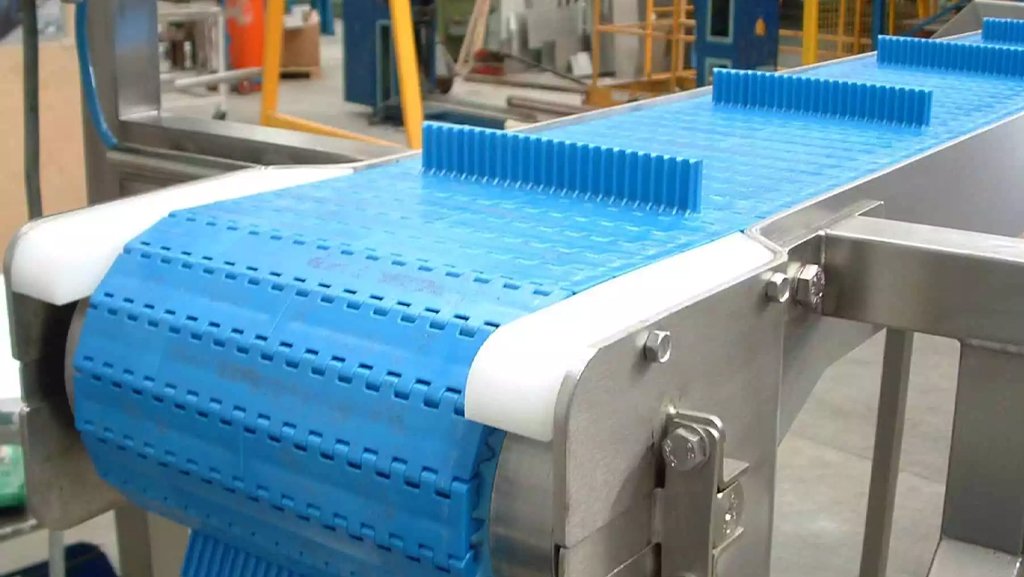

Modular

The modular belt is one of our most complete conveyance solutions. The flexible, versatile and reliable belt allows for conveyance through inclined, horizontal and helical paths, as well as facilitating 90 and 180 degree turns. The belt is low maintenance and can be supplied in dimensions tailored to your needs.

PU

The PU belt, as its name suggests, is manufactured from polyurethane. If you require a belt that can stand the rigours of food processing, there are few more capable solutions than this sturdy conveyor. The PU belt is resistant to grease, oils, water and other liquids. It is also comfortable handling everything and anything from delicate food substances to large packages.

Spiral

For any facility that operates on more than one level, the spiral belt can present an excellent choice. Working along a spiralling, inclined plain, this extremely useful conveyance solution allows for products and materials to be transported from one level to another. Depending on the requirements of a customer, this belt can be supplied in a number of different widths and heights.

Slat

A flexible belt that presents the ideal solution should a facility be short on floor space. The slat belt is perfectly placed to deal with complex loops, winding routes and tight corners. In general, this belt is best suited to use with smaller, lighter-duty items.

Belt Conveyors for Food Processing Applications

Types of belt conveyors available for Wrightfield include, PVC Polyurethene Silicone, PVC , PU Belt (white or blue) Tef;lon, Wire belt, Food belts, Activated Roller Belts , Modular belt and Thermodrive. If you are looking for a belt that isn’t listed then please call on 01379 872800.

Belt conveyor configurations include

- Higher grip belts for anti slip conveyor applications that typically require an element of incline

- Belts designed to alter the direction of your production line and go around curves and awkward corners ( often found when re configuring a production line within an existing building)

- Narrow belts that are often needed when a single width item is required to transported a long distance across a factory production environment

- Floor to Floor belt conveyors are available as flighted belts or modular belts. We have seen an increase in these being used where companies need to optimise floor space by installing mezzanine floor areas to increase working area.

- Intralox conveyors – Wrightfield are partnered with Intralox and are able the complete range of Intralox conveyors. The Intralox range of modular plastic belting is made from plastic modules that are interlocked creating a very strong belt conveyor. Intralox are also teh inventors and manufacturers of Activated Roller Belt conveyors.

Click on the following link to find out more about belt conveyors or this link for information on other stainless steel equipment manufactured by Wrightfield.