Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

A cone deboning line can help to facilitate fast, cost-effective and hygienic deboning of chickens, turkeys and other poultry. In this post, we discuss the subject in further detail.

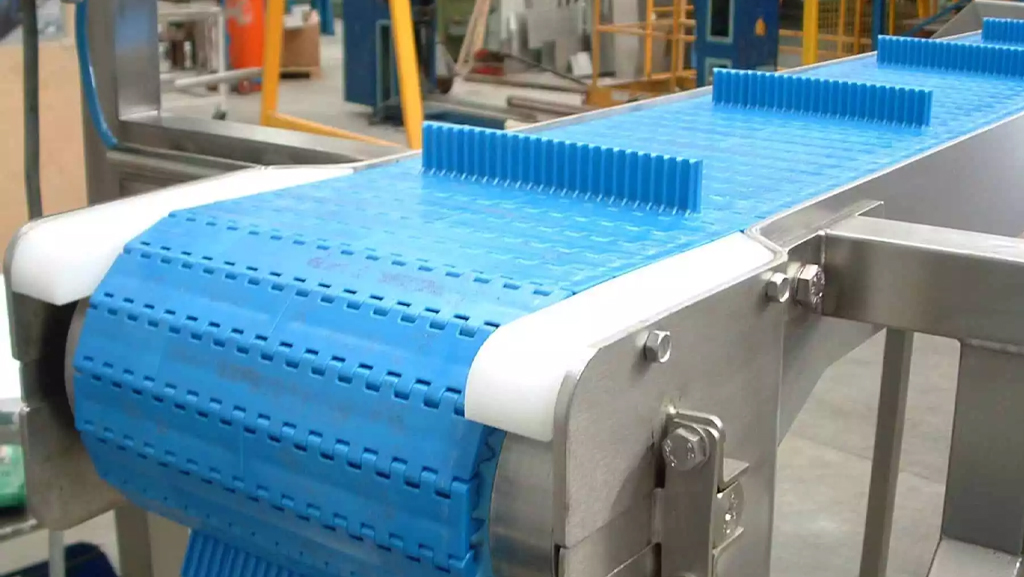

A cone deboning line is a type of industrial equipment used in the process of deboning poultry, such as chickens or turkeys. The process begins by hanging the birds by their feet on a conveyor belt, which carries them through various stages of the deboning process.

The first stage of the cone deboning line is the cone itself, which is a cone-shaped device that the bird is placed in. The bird is then secured in the cone by its legs, which are clamped in place. The cone is then rotated and the bird is pulled through the cone, which separates the meat from the bones.

The next stage is the removal of the breast meat, followed by the removal of the legs and wings. The final stage of the process is the removal of the remaining meat from the bones, which is typically done by hand.

Cone Deboning

Pace deboning does not require workers to be skilled, instead an operative will concentrate on just one single cut, which they will make repeatedly on respective birds. Conversely, the operatives who work on a cone deboning line tend to be skilled workers who know how to make various different cuts to a single carcass.

With the right workers, this is a method that is particularly effective on non-uniform carcasses, where it minimises wastage and optimises yield. This method has the potential to deliver some of the best sales and profit margins in the industry. This high level of profitability is due to the volume of high-margin meat produced.

The typical layout of a cone deboning operation is to have operatives line up in a row, each one manning their own station.

Wrightfield Cone Deboning Lines

As industry experts, we understand the utmost importance of cleanliness. For this reason, hygiene is at the heart of the design of our cone deboning lines.

Made from stainless steel, our lines are extremely sturdy. They offer excellent structural integrity – providing a solid surface on which to work for operatives – and represent a long term investment for a company.

Moreover, the robust lines are very resistant to corrosion – even in the face of the industrial strength liquids used in food processing. This is a factor that ensures that the lines are easy to clean and facilitate sanitation at all times.

Cone Deboning Line – Find Out More

Click on the following link if you would like to find out more about cone deboning line, or this link for information on other stainless steel equipment manufactured by Wrightfield.