Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

The importance of conveyor belt design is something that should not be overlooked. With more than 20 years of experience in the industry, we understand that food processing is a varied and complex business.

No two companies and no two operations are the same. For this reason, we design conveyor belts to suit the individual needs of a customer. This includes conveyor belt design featuring tailored widths and lengths.

Belt Types

Slat Belt – with an innovative hinge design, the slat belt is able to handle complex loops and tight corners. This can help to make this particular type of belt ideally suited to facilities in which space is at a premium. The belt is generally used in conjunction with smaller, light duty products.

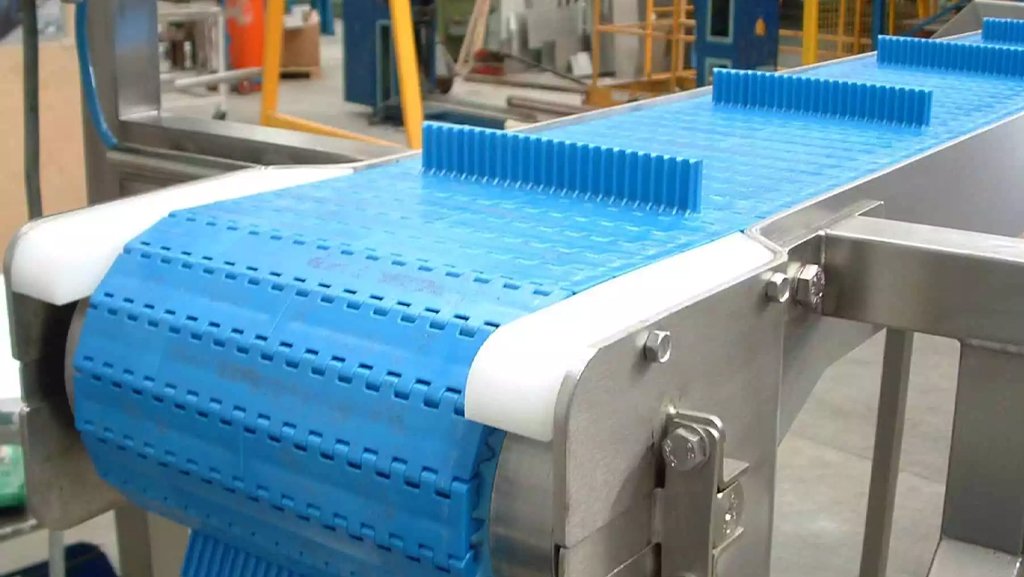

Modular Belt

The modular belt is something of an all rounder in the food processing industry. This belt offers not only flexibility and versatility but reliability too. The belt permits products to be conveyed through inclined, helical and horizontal paths. It also allows for 90 and 180 degree turns.

PU Belt

The PU, or polyurethane, belt is an extremely robust conveyance solution that is resistant against liquids and industrial strength cleaning fluids.

Transference Solutions

If a factory has more than one line it can be necessary to transfer products from one to the other. Similarly, if a facility operates on more than one floor items may be required to be transferred from one level to another. To accommodate for such requirements, Wrightfield manufacture a number of transference solutions including spiral conveyors, transfer conveyors and elevator conveyors.

Conveyor Belt Design – More Information

Click on the following link to find out more about an conveyor belt design or this link for information on other stainless steel equipment manufactured by Wrightfield.