Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

In the fast paced world of food processing, unplanned downtime owing to broken machinery can have serious consequences. We understand this and provide conveyor belt parts to help companies get back up and running as soon as possible.

There are several key parts of a conveyor belt system, including:

- Belt: The belt is the continuous loop that moves along the rollers and is the main component that transports the materials.

- Idlers: Idlers are the rollers that support the belt and help to keep it in place. They are located at the end of the conveyor and along the return side of the belt.

- Pulleys: Pulleys are used to change the direction of the belt and to drive the belt’s movement. The drive pulley is typically powered by an electric motor, while the other pulleys are used to guide the belt.

- Drive Unit: The drive unit is the mechanism that powers the conveyor belt, typically an electric motor or reducer.

- Take-up: Take-up is the device that helps to adjust the tension on the belt. It can be either manual or automatic.

- Support Structure: The support structure is the framework that holds the conveyor belt in place. It can be made of steel or other materials like aluminium and stainless steel.

- Belt cleaners: These are devices that are used to remove material from the belt surface as it moves through the conveyor.

- Skirt board: Skirt board is a material that is used to seal the edges of the conveyor belt to prevent leakage of materials

- Belt splicing: The process of joining two ends of a conveyor belt by mechanical or vulcanizing means.

- Belt tracking: The mechanism or procedure to keep the belt running centrally on the pulley.

Because of the complete set of services we offer we are also able to provide custom built components. We discuss these topics in greater detail below.

The Cost of Conveyor Downtime

The cost of a conveyor belt failing can be significant for businesses, both in terms of financial costs and potential impact on operations. Here are some examples of the costs of conveyor belt failure:

- Downtime: If a conveyor belt fails, it can result in downtime for the production line. Depending on the extent of the damage, this downtime can last for hours or even days. During this time, the business may not be able to produce goods or meet customer orders, resulting in lost sales and potential damage to the business’s reputation.

- Repairs and Replacement: Conveyor belt failure can also result in repair or replacement costs, including the cost of replacement parts, labor, and lost productivity. These costs can add up quickly, especially if the damage is extensive or the conveyor belt is a critical component of the production line.

- Safety Risks: A failed conveyor belt can also pose safety risks for employees, particularly if the conveyor belt is not shut down and secured properly. This can result in injuries or other safety incidents, which can lead to additional costs for the business, including workers’ compensation claims and potential legal liability.

- Environmental Impact: Conveyor belt failure can also have environmental impacts, particularly if the failure results in spills or other environmental hazards. This can result in additional costs for cleanup and potential fines or penalties for non-compliance with environmental regulations.

In summary, the cost of a conveyor belt failure can be significant, including lost productivity, repair and replacement costs, safety risks, and potential environmental impacts. Businesses should take steps to prevent conveyor belt failures through regular maintenance and inspections to minimize the risk of downtime and associated costs.

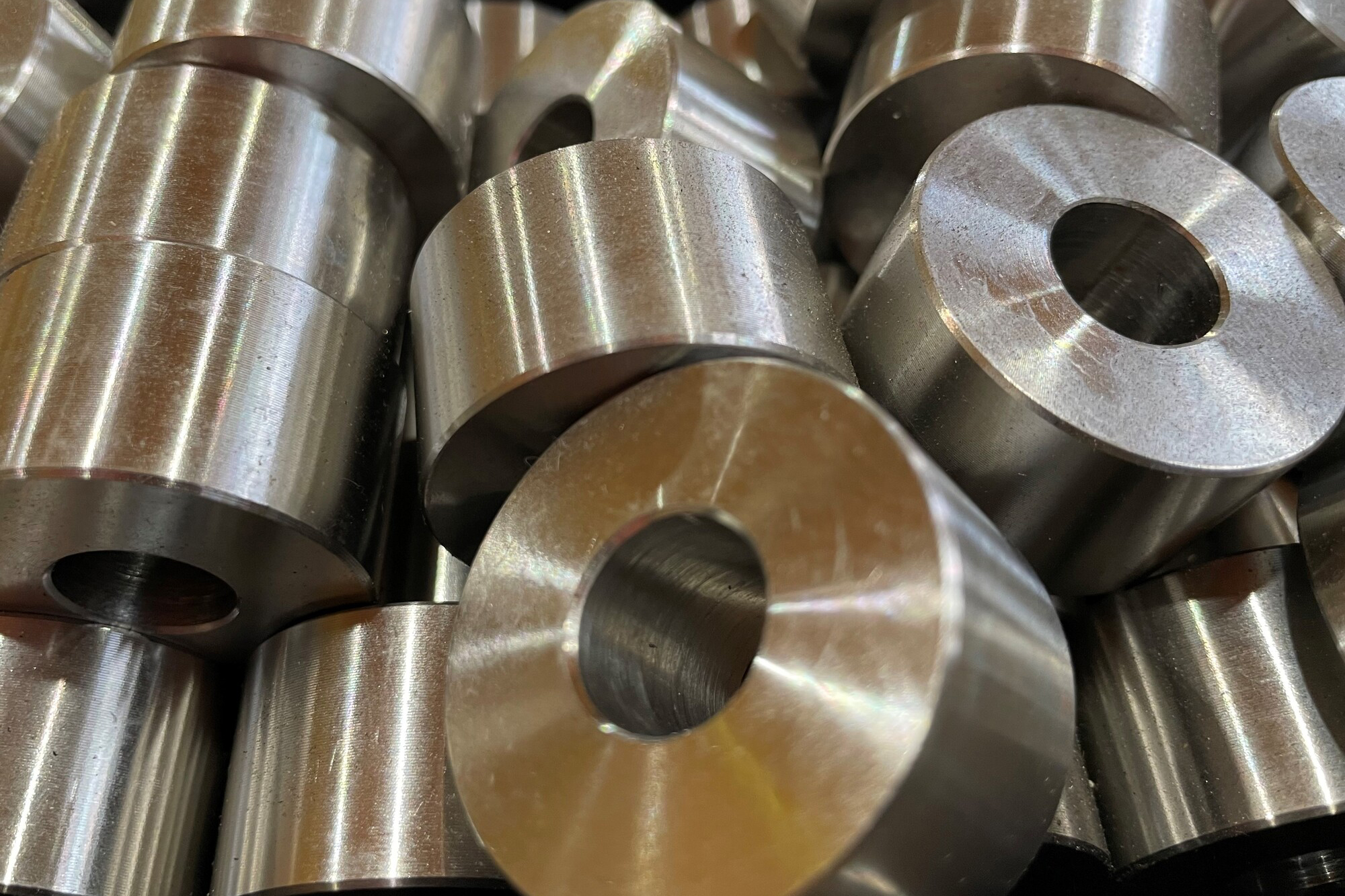

Conveyor Belt Parts – Custom Made Components

The fact that we own our own factory is an important factor in facilitating us to provide the efficient service we do. With no middle man to deal we are able to work directly with clients enabling us to save both time and effort. Moreover, we are in a position to fully understand the requirements of a client. Finally, with our own manufacturing facility, we are able to realise a client’s objectives and to provide them with custom made conveyor belt parts if required.

Conveyor Belt Parts – Aftercare Service

We provide a comprehensive aftercare service, as part of which we supply spare conveyor belt parts and components. Additionally, the service also includes planned maintenance so as to proactively avoid any potential issues that may occur to machines, as well as offering emergency breakdown repair.

More About Wrightfield

Located in Suffolk in the East of England, Wrightfield is an experienced engineering company. We have amassed more than 20 years of experience in the food processing industry. We provide a complete range of services, including design, manufacture, and installation. We aim to provide clients with the highest levels of service and quality during the time we spend working in conjunction with them.

Find Out More About Conveyor Belt Parts

Click on the following link to find out more about conveyor belt parts or this link for information on other stainless steel equipment manufactured by Wrightfield.