Project: Bespoke Food Dicer Rack Objective: The client needed a tailored storage solution for their…

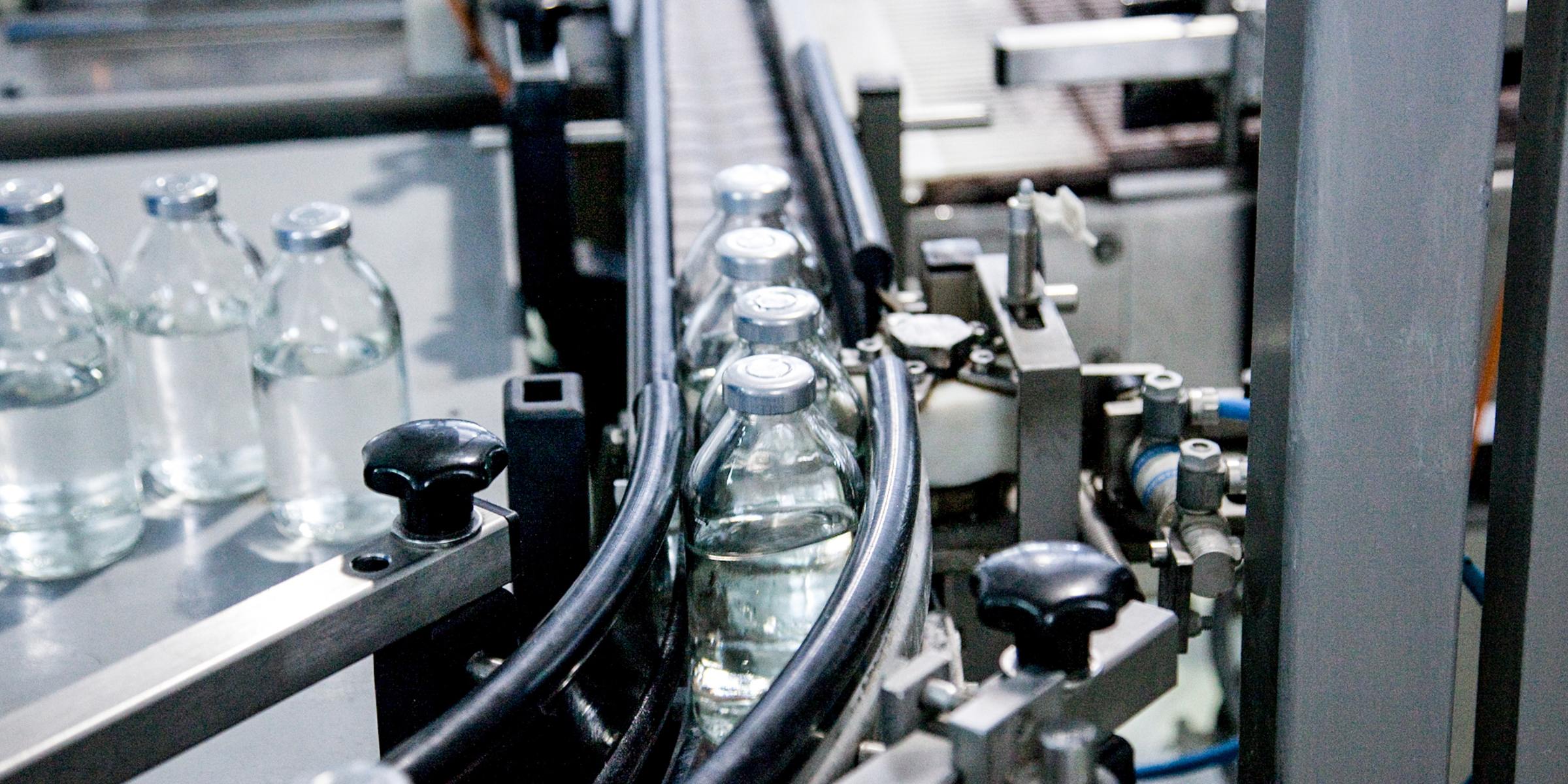

In the fast-paced, high-stakes world of pharmaceuticals, efficiency, precision, and safety are non-negotiable. Whether it’s moving raw materials, packaging, or transporting finished products, the conveyor systems used in these environments must meet the highest standards of hygiene, accuracy, and durability. For many pharmaceutical companies, the solution lies in custom-made conveyor systems designed to meet their specific operational needs.

Here’s why custom conveyor systems may be the ideal choice for the pharmaceutical sector:

Tailored to Specific Processes and Products

Pharmaceutical companies often handle a wide range of products—from small vials and blister packs to bulk powders and fragile items like IV bags. Each of these products requires a different handling approach. A custom conveyor system can be specifically designed to meet the needs of the materials it will transport, ensuring optimal performance for each unique process.

Fragile Product Handling: Custom systems can include features like soft-touch belts, smooth transfers, and gentle handling mechanisms to protect delicate products such as ampoules or liquid vials.

Bulk Product Handling: For more oversized items, a custom system can be built with the appropriate belt widths, strength, and transfer methods to ensure efficient movement and minimal downtime.

Enhanced Cleanliness and Compliance

Pharmaceutical environments demand the highest levels of hygiene to prevent contamination. Off-the-shelf conveyor systems might not meet the stringent cleaning and sterilisation requirements set by regulatory bodies. Custom-made conveyor systems for pharmaceuticals can be designed with specific materials, like stainless steel, that are resistant to chemicals and easy to clean. These systems can also feature clean-in-place (CIP) technology, which allows for automated cleaning without disassembly, ensuring compliance with industry hygiene standards.

Stainless Steel Construction: This durable material is corrosion-resistant and ideal for environments where frequent sterilisation is required.

Easy-to-Clean Designs: Rounded edges, removable belt sections, and minimal gaps prevent debris buildup, making cleaning more efficient.

Improved Efficiency and Productivity

Custom conveyor systems can be designed to integrate seamlessly with existing processes, improving overall workflow and minimising bottlenecks. They can also be engineered to handle high-speed operations, which are crucial in pharmaceutical production lines that must meet strict deadlines and high production quotas.

Optimised Speed and Accuracy: A custom system can be tailored to move products at precise speeds, ensuring proper synchronisation with other machinery on the production line.

Integrated Automation: Custom conveyors can be designed to incorporate sensors, vision systems, and robotics, streamlining processes like packaging, sorting, and labelling to increase productivity.

Space Optimisation

Pharmaceutical facilities often face space constraints, and standard conveyor systems may not fit into tight spaces or odd layouts. A custom-made conveyor system can be designed with specific dimensions and configurations to make the most of available space, whether it’s a narrow, high-traffic area or a complex, multi-floor facility.

Compact Designs: Custom systems can be designed to fit within tight footprints, maximising space without sacrificing functionality.

Multi-Level Systems: For facilities with limited floor space, custom conveyors can be engineered to transport materials vertically and efficiently using overhead space.

Reduced Downtime and Maintenance

Standard conveyors may not be ideal for the heavy use and continuous operation typical in pharmaceutical manufacturing. A custom system can be built with long-lasting components designed for the specific demands of the production line, reducing the risk of breakdowns and minimising downtime.

Durable Components: From high-quality motors to wear-resistant belts, custom conveyors can be outfitted with components that are built to last, reducing maintenance needs and increasing uptime.

Easy Access for Maintenance: Custom designs can also include features like easily accessible panels and tool-free belt removal, making routine maintenance quicker and more straightforward.

Flexibility for Future Growth

Pharmaceutical companies often expand or modify their production lines as they develop new products or scale operations. A custom conveyor system can be designed with flexibility in mind, allowing for easy adjustments or expansions as needed. Modular components, adjustable speed controls, and adaptable conveyor paths can help ensure that the system remains effective as the company grows.

Modular Design: Custom conveyors can be built with interchangeable sections, allowing easy adjustments or future expansions.

Variable Speed Controls: With custom speed settings, the conveyor can adapt to changes in production rates without requiring a complete system overhaul.

Integration with Specialised Equipment

Pharmaceutical production lines often require the use of specialised equipment like filling machines, vision inspection systems, or robotic arms. A custom conveyor system can be designed to seamlessly integrate with this equipment, ensuring smooth transitions between processes and eliminating manual intervention.

Automated Control Systems: Custom conveyors can be programmed to work in sync with other machines, creating a fully automated, high-efficiency production line.

Vision Systems Integration: For quality control, custom conveyors can incorporate cameras and sensors to ensure that only correctly filled and sealed products move forward.

For pharmaceutical companies looking to optimise their production lines, custom-made conveyor systems offer a range of advantages, from increased efficiency and flexibility to improved compliance with hygiene standards. By designing conveyors to fit the exact needs of the product and process, pharmaceutical manufacturers can ensure smoother operations, reduce downtime, and maintain the highest levels of safety and precision.

Investing in a custom conveyor system is not only a wise business decision—it’s a strategic move that supports both immediate production goals and long-term growth in a competitive, highly regulated industry.

Contact us today to learn how a custom conveyor system can improve your pharmaceutical production line!