Pallet Conveyors

Pallet conveyors improve the efficiency of processes that involved the receipt, handling and dispatch of pallets. … Every pallet conveyor system can be integrated with other onsite equipment, feeding to and from palletisers, pallet lifts, pallet weigh stations, wrappers, hooders and strappers

Radius Conveyors

Wrightfield radius and s-conveyors are designed to change the direction of products without changing their orientation on the processing line. Available as a standalone conveyor or as part of a complete conveying system. Wrightfield custom designed and built radius conveyors provide a high-performance, solution to changing the processing line’s direction.

Shuttle Conveyor

These units are suitable for transferring product from a much wider belt to a narrow-size belt and vice versa, this can be dependent on the specified shuttle stroke. Shuttle conveyors typically come with a variable-speed electric motor drive as standard though other drive options are available

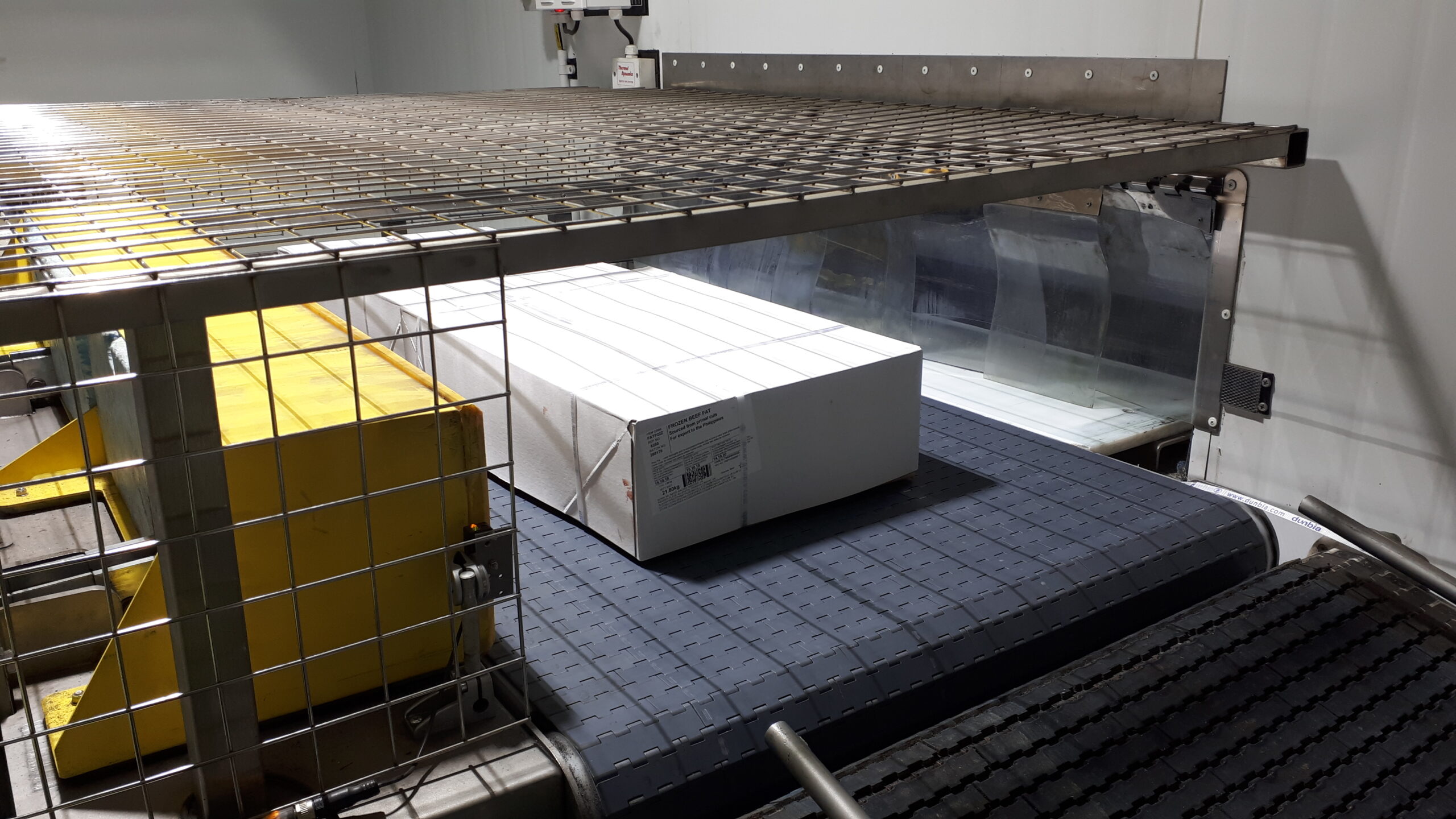

Transfer Conveyors

The Wrightfield transfer conveyor is designed for the transference of products/materials to other belt systems. Each conveyor is designed specifically for the customer’s purposes with only the finest quality components and materials used in the manufacture. We design with hygiene being a top priority at each stage of production

Unpowered Conveyors

Gravity conveyors are unpowered conveyors such as a gravity chute or a roller conveyor that uses gravitational force to move materials over a downward path. When an item has sufficient weight to allow them to move unassisted downwards, usually on an inclined runway then a gravity conveyor can be used for transporting articles. A gravity conveyor can utilize skatewheels or full rollers

Freely rotating tubular rollers located on a fabricated framework, assembled in longitudinal sections and slightly inclined that help the load move under gravity is another type of gravity roller conveyor.

Perfect For Conveying Lightweight Items

Gravity flow skate wheel conveyors are an economical option for conveying lightweight cartons, trays, or boxes. They are used extensively in goods in / goods out (shipping/receiving) and assembly areas. Skate wheel conveyors reduce manual material handling of lightweight items over short distances. Any items with a smooth, flat bottom can be moved with skatewheel conveyors: boxes, carriers, sheets, flat bundles, creates, cartons, flat bags, selected totes. These items can be wider than the conveyor; 150mm over on each side is not too much. Extra wide items like sheet wood, can be moved but must be centred carefully.

Gravity Conveyors – Conveyor Types Skatewheel or Roller

The places you use gravity roller conveyor are mostly the same as skatewheel, with some significant differences in the type of load. Roller conveyor is more expensive than skatewheel, and can be more effective, dependent on what’s being moved. Items with an uneven or open bottom, or with a rim on the bottom should be conveyed on rollers. As a rule of thumb these items should never be bigger around than the rollers are long. For information on other conveyor types click here

Conveyor Types – Long term Structural Integrity of Stainless Steel

Because of the highly resistant nature of the material from which they are manufactured, stainless steel conveyor systems offer long term structural integrity. The conveyance solutions also offer plenty in the way of longevity thanks to their solid structure. As such, stainless steel conveyor systems can run efficiently over many years, providing consistent and long term service.

Find Out More about Conveyor Types

Click on the following link to find out more about stainless steel conveyor systems or this link for information on other stainless steel equipment manufactured by Wrightfield.