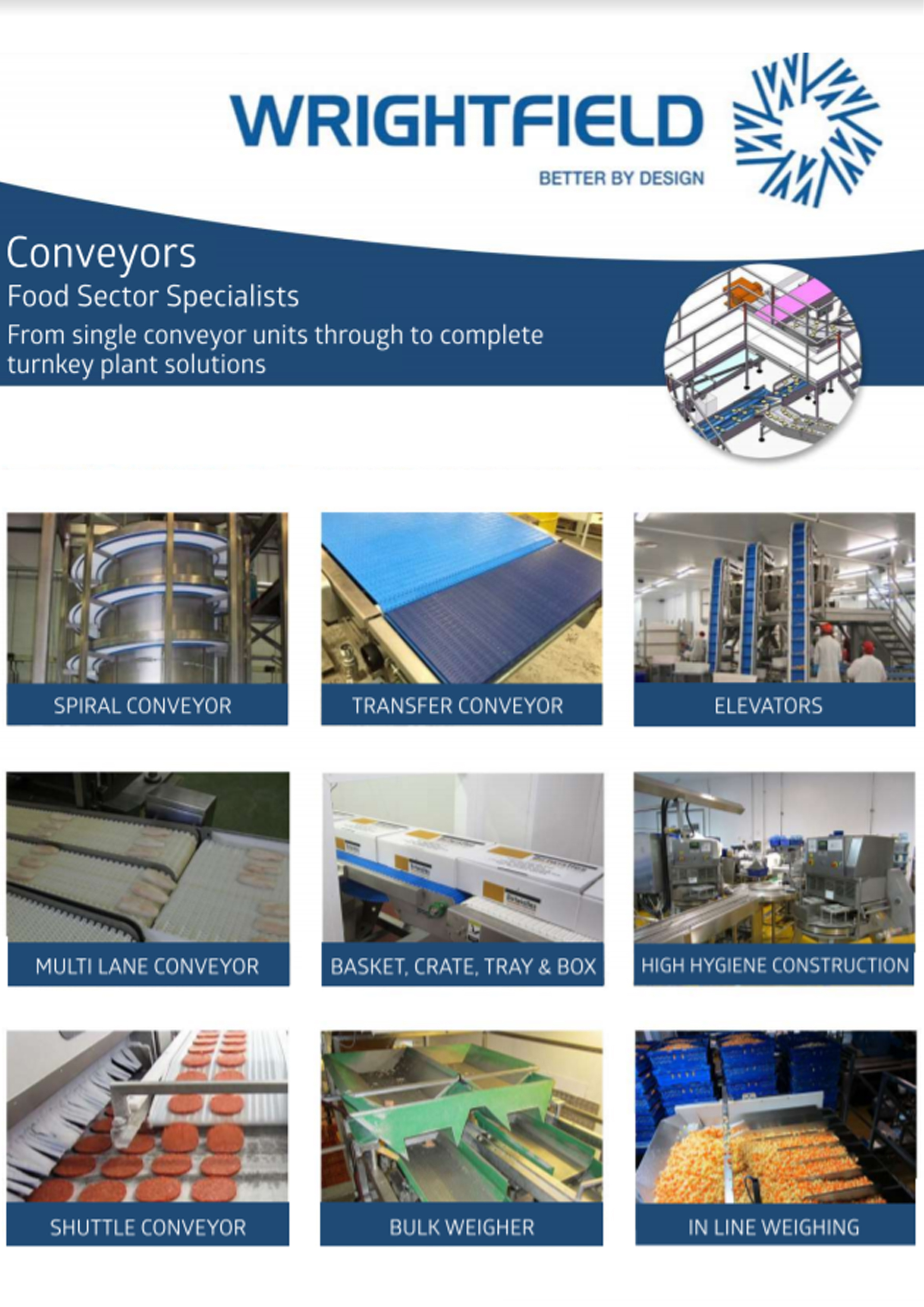

Bespoke conveyor integration is of paramount importance and can assist with streamlining processes, offering large savings across production. The new equipment you select needs to be the right choice to fit into your space and work effectively with your other processing and production equipment including existing conveyors.

Working with an expert partner like Wrightfield ensures you have the expertise required to assess your current equipment and help choose or design the new conveyor to fit in and work effectively. Custom design is possible and often the best solution to ensure the conveyors integration within your factory are setup to work in the optimal condition for your business.

Working within the Poultry, Meat, Ready Meal and Pet food sectors integrating with

- Portion control

- Weighing machines – including multi head weighers

- Sealing equipment

- Labelling and Packaging

- Metal detection technology

Wrightfield offer the complete integration solution to ensure seamless integration between old and new conveyor systems

Contact Us About Automated Conveyor Integration

The following brochures and data sheets are available as PDF downloads. If you would like a printed version please contact us and request

After Sales Conveyor Maintenance

Wrightfield offer a professional and responsive after sales service. Including both spares & various service options we can help keep your business up and running.

As partners of both Intralox (for the full range of belts) and SEW for motors, along with our ability to source from a range of manufacturers, as well as being able to manufacture or fabricate a variety of bespoke parts we are confident we can meet your needs, so why not give us a try when you next need replacement parts

We can provide planned maintenance on a scheduled basis, and well a providing skilled engineers for shift cover in the event of busy periods or holidays.

Our fully equipped vans are on call in the event of a breakdown.

Our After Sales service offerings can be bespoked to your particular requirements including:

- Mechanical

- Electrical (17th edition qualified)

- Control systems

- Belts, Motors & wide range of other purchased parts

- Manufacturing, Welding & Fabrication available in-house

- Breakdown Support

- Service Contracts

- Shift Cover

- Planned Preventative Maintenance

- Audits & Assessments

- Remote Diagnostics

Conveyor Spare Parts

Belt Conveyor Components

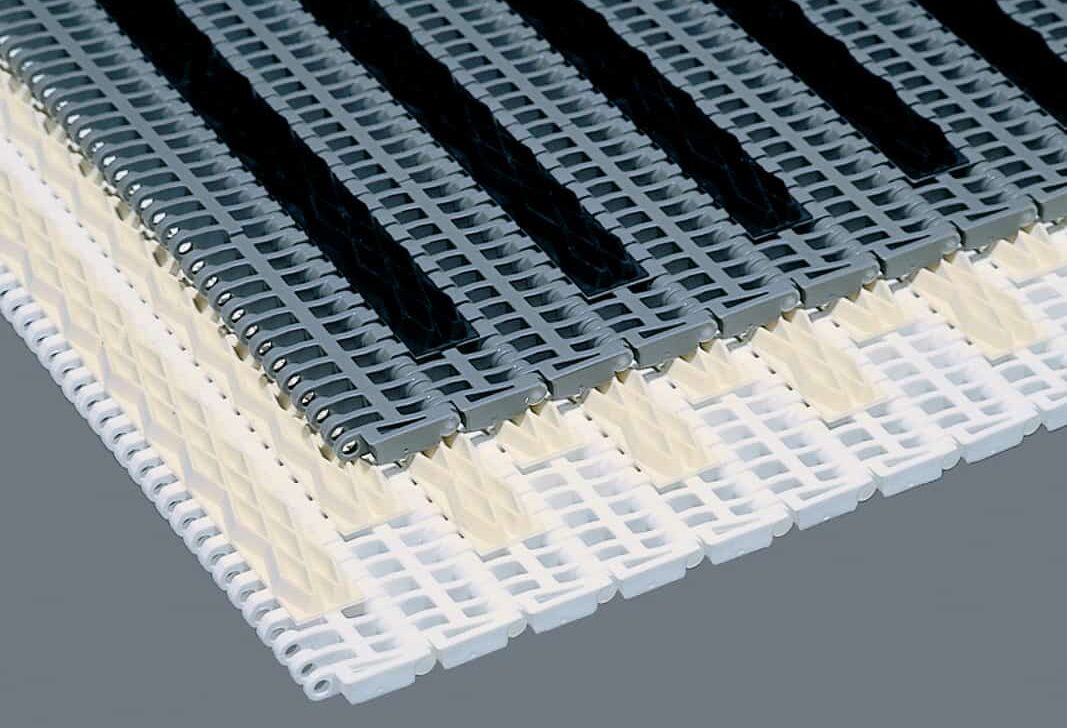

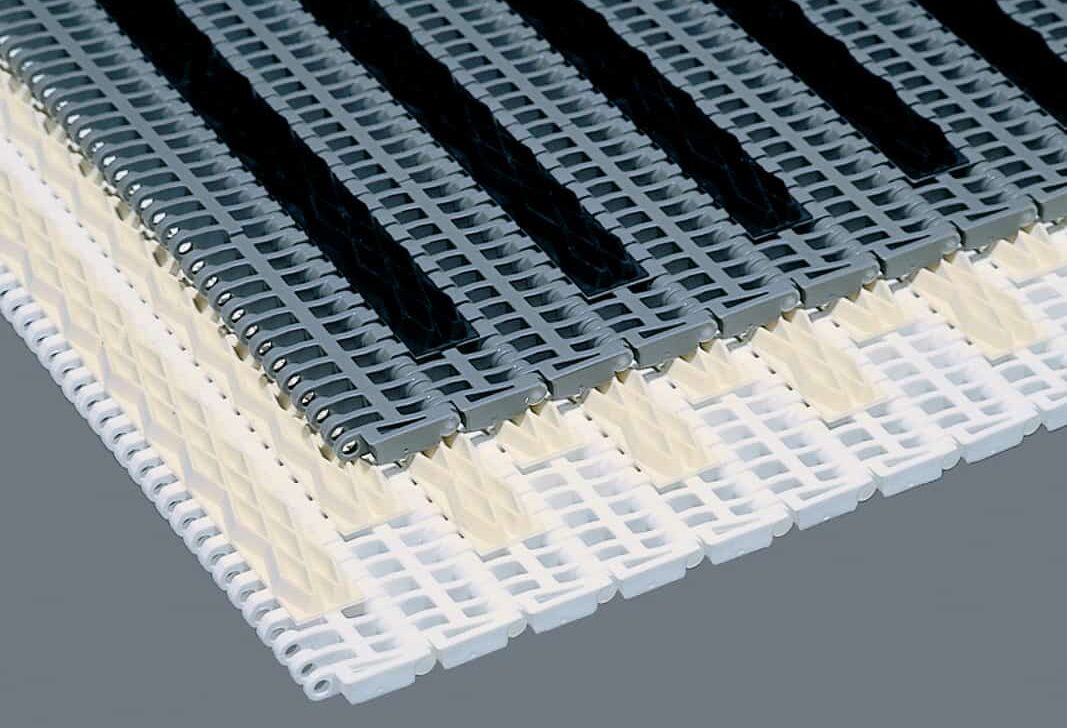

We supply Conveyor Belting of all types including Food Grade Conveyor Belting, Grip-top Belting, PVC Conveyor Belting, Smooth. Belt Conveyor Components are available for all types of Belt Conveyors and include Drive Drums, Idler Rollers, Crowned Rollers and Motors.

- Conveyor Belting – Smooth and Grip-face belts are available to suit a variety of applications. These are available in a variety of different colours.

- Roller Drums – Drums are available to suit Wrightfield conveyors and other suppliers of belt conveyors

- Bearings – We have a range of replacement belt conveyor bearings available from stock.

- Sprockets and Drive chain – we have a range of replacement sprockets and drive chains available from stock. Non stock items can be obtained

- Knock our Rollers – We have a variety of replacement knock out rollers available. Over the years we have manufactured rollers to suit conveyors that have been manufactured but the original manufacturer is no longer able to support / supply

- Adjustable feet – We have a range of steel, plastic, steel, light and heavy duty adjustable feet available. We also manufacture bespoke feet that allow the height of a conveyor system to be raised ( which can provide a very cost effective way of adapting an existing conveyor system

- Stainless Steel Ball Units – We are able to offer stainless steel ball units.

- Geared Motor Units – We stock SEW geared motor drives for all of our conveyors, including lineshaft conveyors, belt conveyors,pallet conveyors,belt under roller conveyors and our flexible conveyors.

- Intralox – we stock a range of Intralox components

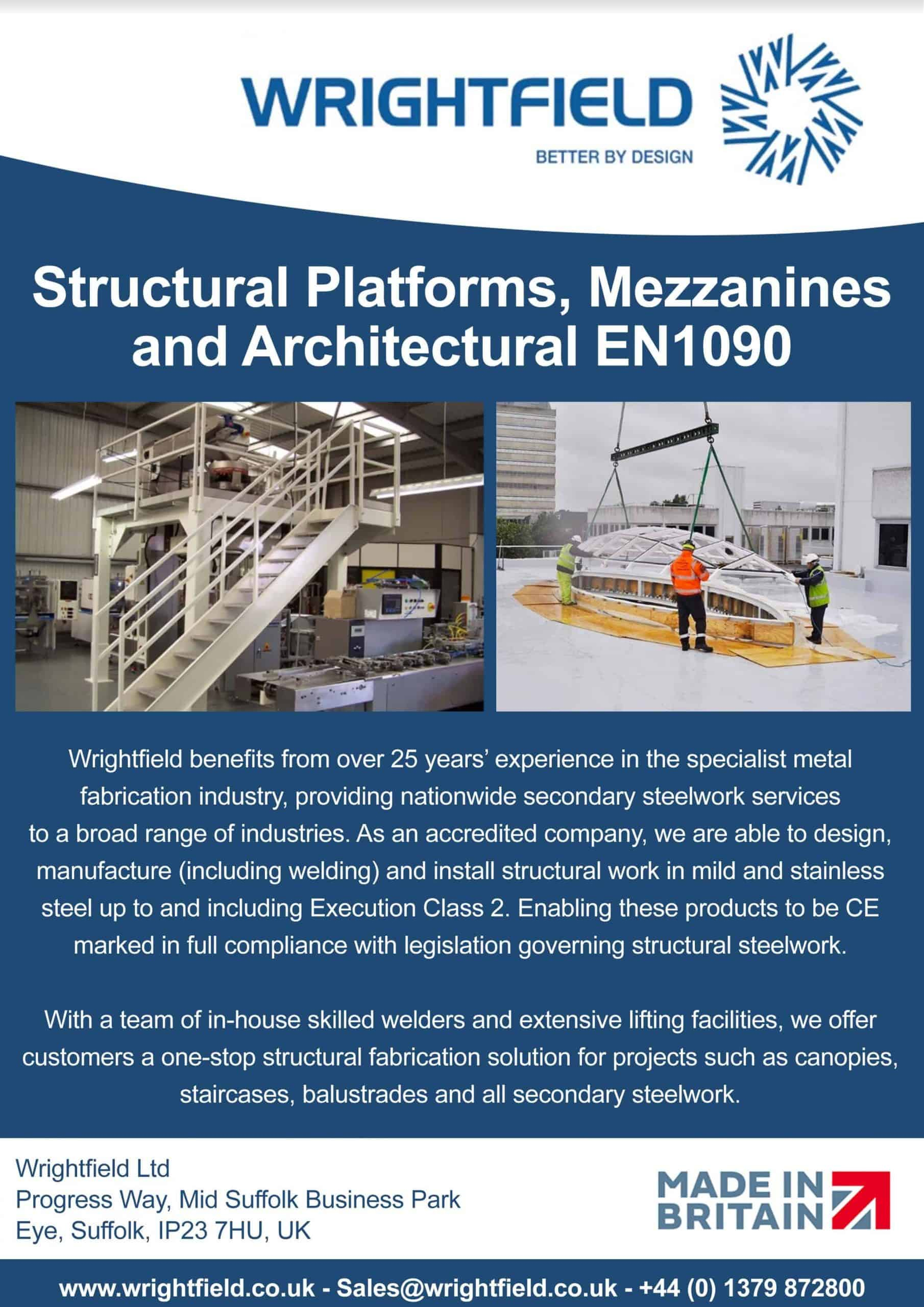

In the fast paced world of food processing, unplanned downtime owing to broken machinery can have serious consequences. We understand this and provide conveyor belt parts to help companies get back up and running as soon as possible. Because of the complete set of services we offer we are also able to provide custom built components. We discuss these topics in greater detail below.

Conveyor Belt Parts – Custom Made Components

The fact that we own our own factory is an important factor in facilitating us to provide the efficient service we do. With no middle man to deal we are able to work directly with clients enabling us to save both time and effort. Moreover, we are in a position to fully understand the requirements of a client. Finally, with our own manufacturing facility, we are able to realise a client’s objectives and to provide them with custom made conveyor belt parts if required.

Conveyor Belt Parts – Aftercare Service

We provide a comprehensive aftercare service, as part of which we supply spare conveyor belt parts and components. Additionally, the service also includes planned maintenance so as to proactively avoid any potential issues that may occur to machines, as well as offering emergency breakdown repair.

The following articles may be of interest when considering conveyor selection or operating requirements

Frequently Asked Questions on Modular Belt Conveyor Systems

1. Can modular belt conveyors be run on an incline? This depend on your product but usually up to 45 degrees can be achieved without flights…

Conveyor Systems are mechanical devices or assemblies that transport materials, components, products or food with minimal effort.

Whilst there are a numerous different kinds of conveyor systems, they usually follow a standard configuration.

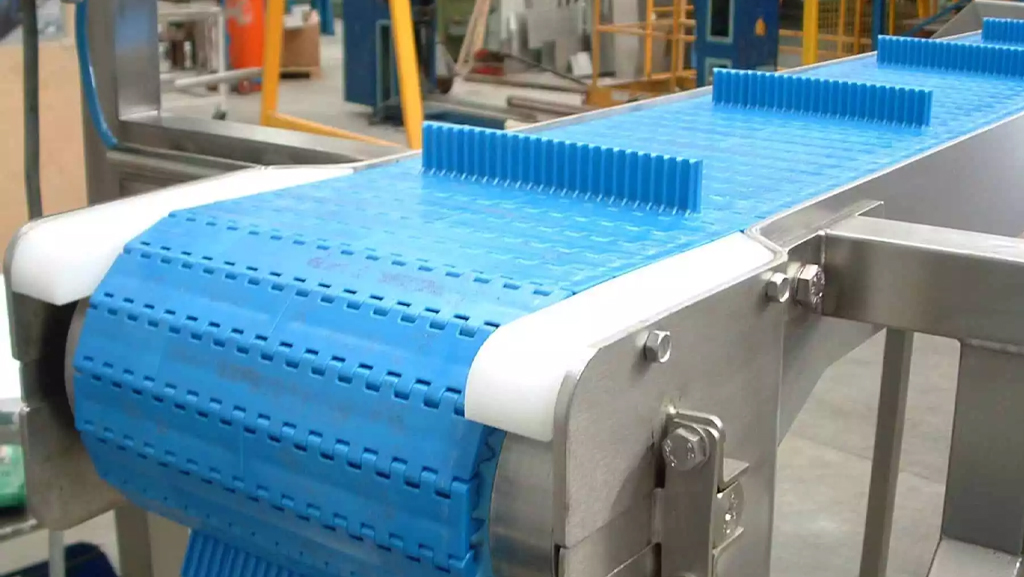

Plastic modular belts are perfectly suited to going round bends and curves

They can be easily repaired ( in the event of a breakage) and extended should the need occur. This has the advantage that the plastic belts can be changed quickly.

There are three main industrial classes of belt conveyors; food processing conveyors, general material handling and bulk material handling.

The conveyor belt system you need will depend on what your transporting, the speed it…

A conveyor system is fundamentally an assembly of different conveyors ( they could be the same type within different production stages , or different types of conveyors) that are assembled together to transport materials (from start to finish) with the minimum of effort compared to doing the transporting the goods manually

Essentially a conveyor system comprises of a frame which supports the conveyor mechanism ( which could be either gravity fed or powered) .

Conveyor systems are used in a wide variety of industries as a standard item of mechanical handling equipment to move products, raw materials, food products, ingredients, goods, raw goods, and an almost limitless set of other materials from one location to another, usually within the same production area or building.

Because they remove a significant element of manual handling they are extremely handy for businesses that deal with bulky goods, heavy items, raw materials, and mass-production items.