Conveyor Belt Types

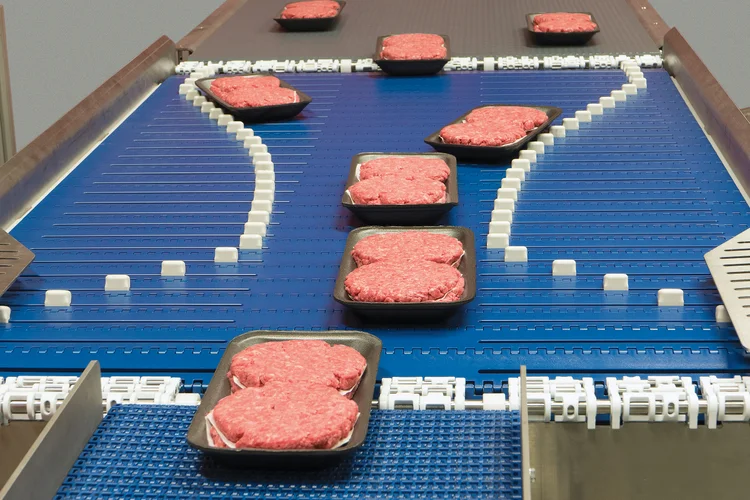

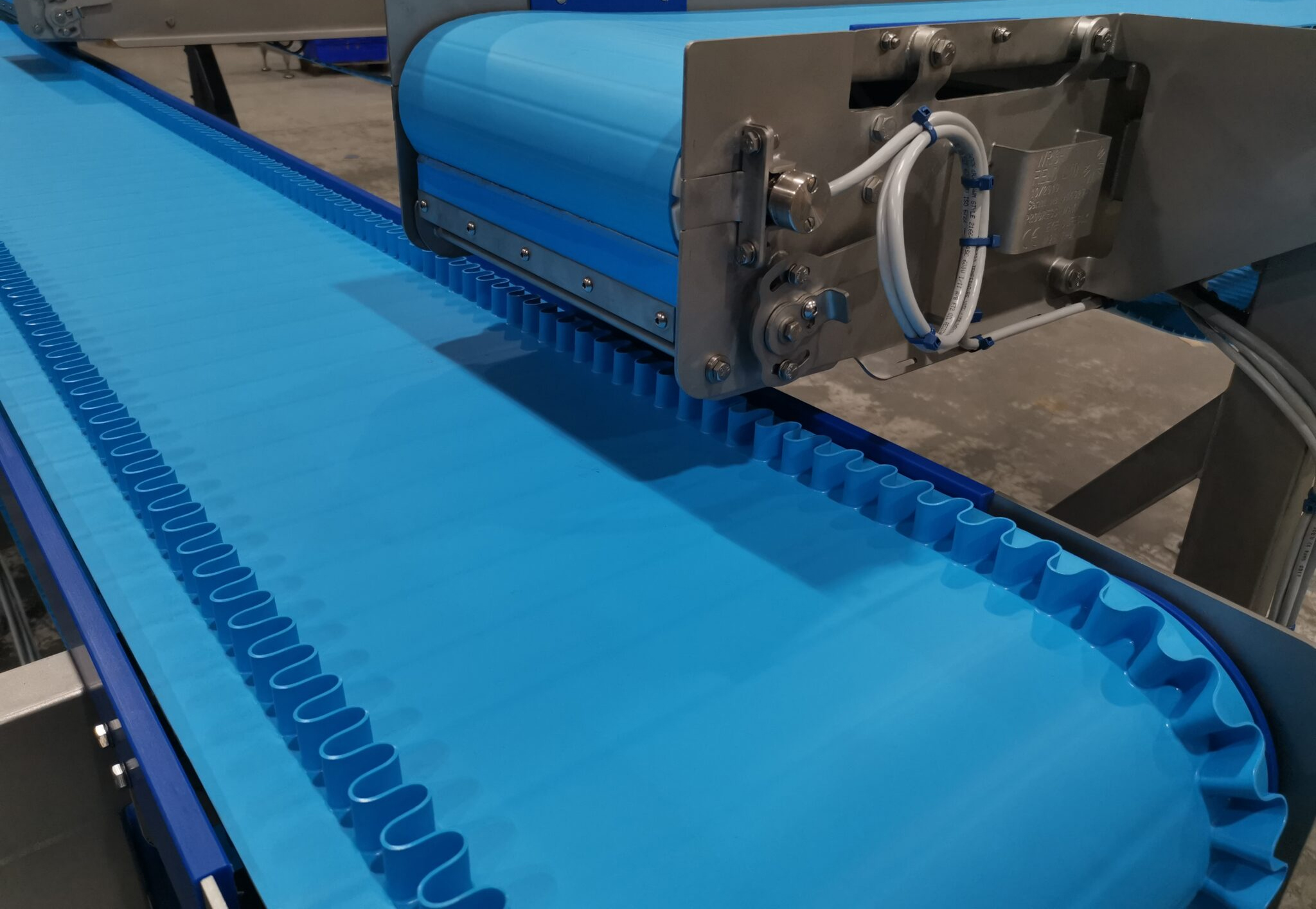

Conveyor belt type can fall into many categories, depending on the manufacturer. The application always dictates the materials, construction, and style of the belt used. Some are gentle enough to transport prawns / delicate foodstuffs while others can handle the impact of routine pallets and bulky heavy items.

Manufacturers, Food processing plants, factories and distributors relied heavily on human labour and manual handling before the advent of conveyor belts. The manual handling of products placed worker health and safety along with product quality in jeopardy. The simple system of rotating pulleys and belts streamlines product handling in every product-driven industry today.

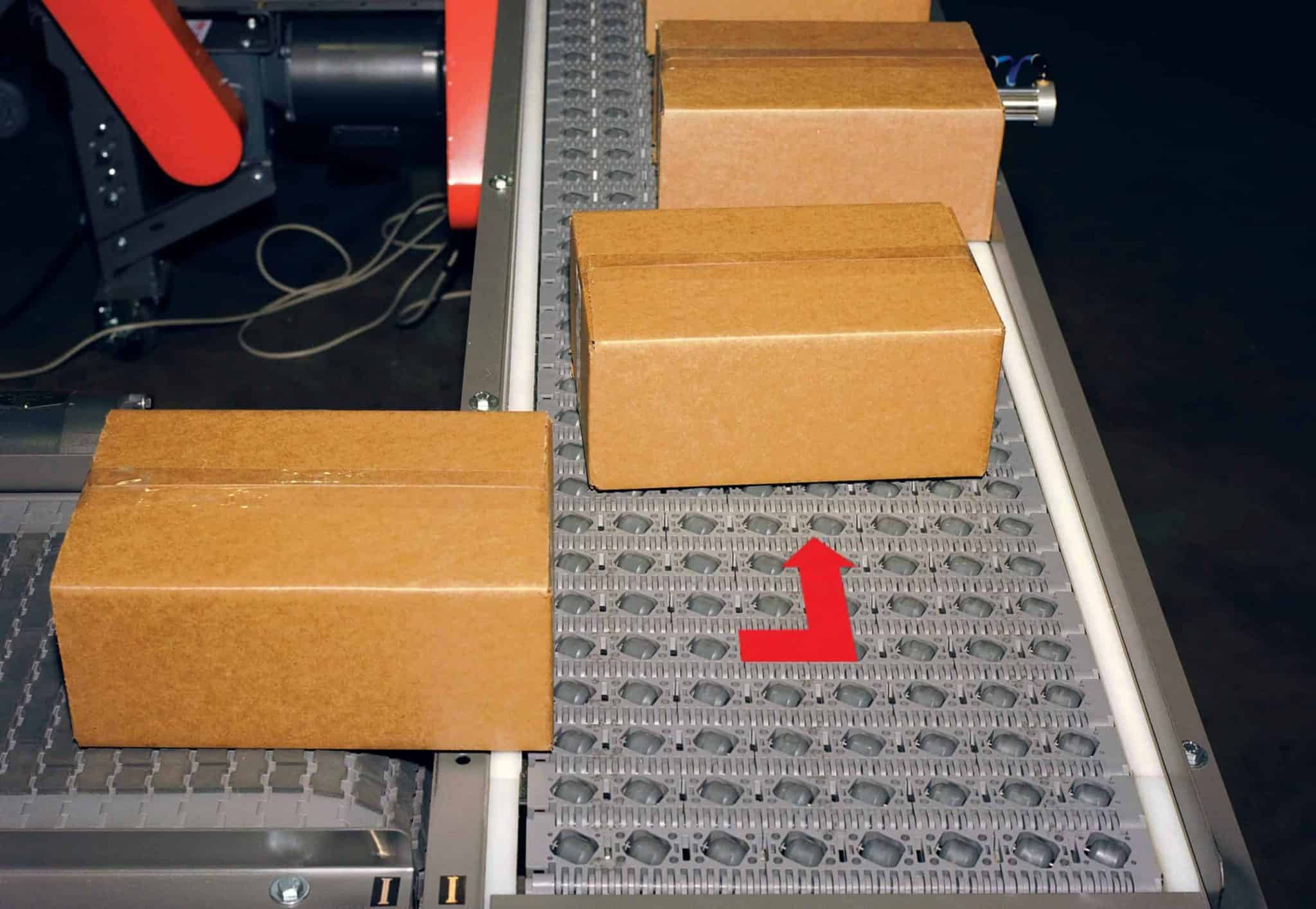

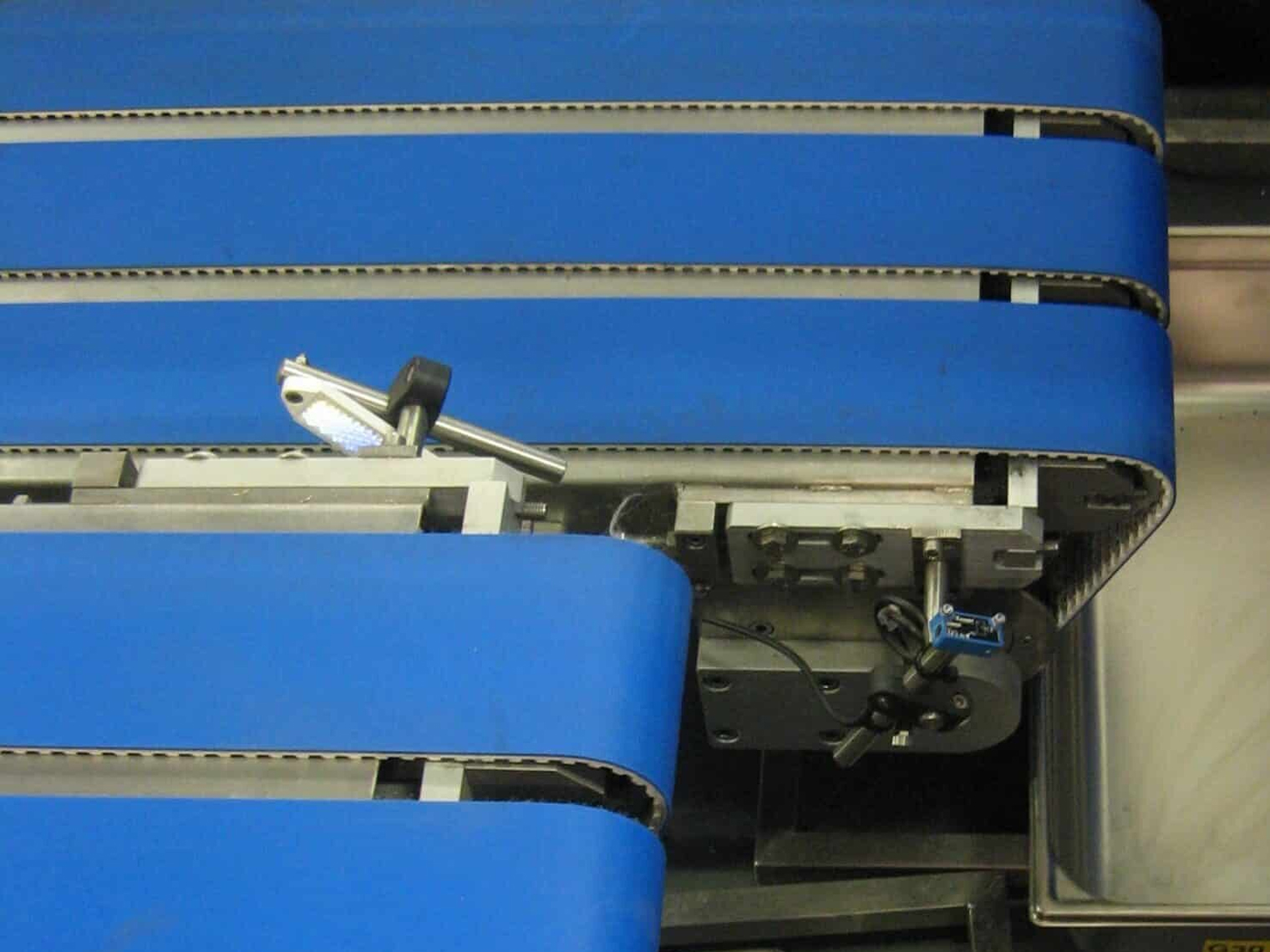

The technology used in conveyor belts now has developed significantly from the the simple belt systems of the past. The active integrated motion (AIM) conveyors are a great example of how conveyors have been developed Companies choose modern belts based on the use case. For example, a metal belt would not handle precious stones or delicate products well. Material handling companies that understand different types of conveyor belts and their uses can choose the safest and most efficient conveyor systems for their needs.

Consider some of the most widely used conveyor belt type materials and their applications:

Solid, general-use belts.

- The most common conveyor belts are general-use belts. These solid belts typically feature materials including rubber or a fabric such as nylon, polyester, neoprene, or nitrile.

- Belt properties determine the conveyor belt’s primary applications. For example

- Retail outlets commonly use PVC conveyor belts

- Airports may use neoprene, polyester, or rubber for luggage handling.

- Mining and milling industries commonly use rubber to handle bulk materials including raw ore and aggregates.

- Food production facilities – will use a mixture of modular belt, Thermodrive, Polycord, wirebelt, slat and PU

These materials may feature different coatings, thicknesses, and arrangements to deliver a range of handling properties. Some offer food safety ratings while others perform well in high temperatures. Other common properties of general-use belts may include high or low friction levels and specific bulk-handling structuring.

Wrightfield Pools a sister company of Wrightfield design and manufacture stainless steel pools and movable pool floors also