Project: Bespoke Food Dicer Rack Objective: The client needed a tailored storage solution for their…

At Wrightfield, we specialise in creating bespoke conveyor solutions tailored to our customers’ specific needs. In a recent project, we worked closely with a large food processor to design and manufacture a hygienic conveyor system for handling raw meat products.

Key Highlights:

Consultative Design Process: We collaborated with our customer to understand their unique requirements. This resulted in a custom conveyor system with three independent lane process machine outfeed conveyors, which fed a twin lane packing conveyor.

Ergonomic and Efficient: The twin-lane conveyor with split levels for ergonomic drag-and-drop product transfer ensures that operatives can work comfortably and efficiently. This feature was designed to improve the packing process by allowing easy transfer of raw products into trays.

Precision in Product Handling: To handle delicate raw meat products, we ensured tight product transfers across all conveyors, minimising the risk of damage.

Integrated Control Systems: The system offers flexible operation, and it can be controlled centrally or independently through remote panels, catering to various production needs.

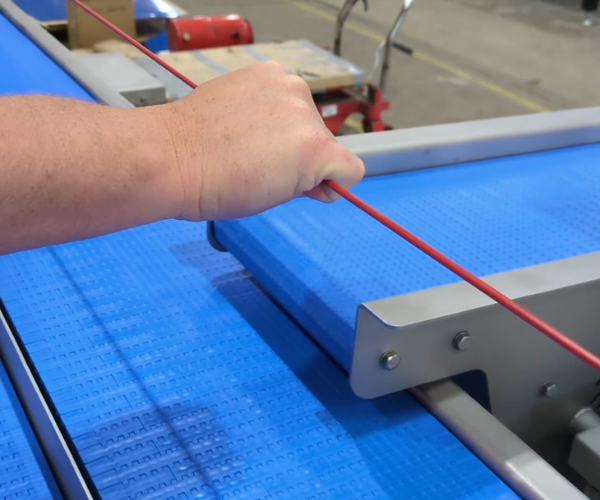

Comprehensive Safety Measures: For enhanced safety, the twin-lane conveyors are equipped with remote E-stops and a global pull cord E-stop function, ensuring complete control over the system in emergencies. Please watch the video to see a demonstration.

Wrightfield’s consultative approach and expertise in customised conveyor systems ensure that every solution aligns precisely with the client’s operational goals and safety standards.

Our primary objective is to deliver conveyor systems that integrate seamlessly into your workflow. Trust our expertise to enhance your production process with innovative and reliable solutions.

To discuss your bespoke conveyor system, contact our sales office on 01379 872800.