Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

At Wrightfield, we are industry experts who understand that food processing is a highly competitive business. Therefore, we design and manufacture a comprehensive range of bakery weighing solutions that can help to give your company the edge – we discuss further in the following post so please continue reading if you would like to find out more.

There are several different types of automated systems and solutions that can be used for bakery weighing. One common solution is the use of digital scales, which can accurately weigh ingredients and finished products.

Another solution is the use of weigh fill systems, which are designed to automatically weigh and dispense ingredients into containers or packaging. Additionally, some bakeries may use computerised recipe management systems, which can help to ensure that the correct amount of ingredients are used in each recipe.

Other possible solutions include using automated packaging and labelling systems, which can help to streamline the packaging and labelling process.

Automated Bakery Weighing

Our highly automated bakery weighing solutions are able to weigh baked goods at high speed, helping to increase accuracy and accelerate production while simultaneously minimising manual intervention and giveaway.

Benefits of Automated Systems

- Efficiency: our automated systems are able to run day in and day out with minimised downtime. They also deliver low operational costs, a benefit achieved through reduced manual labour requirements.

- Compatibility: additionally, our systems are designed to integrate seamlessly with any existing systems and infrastructure that may already be present in your current operation.

- Flexibility: should you need to change layout and package format, this can be done quickly and easily using the user friendly interfaces of our products.

- Hygienic: as with all of our food processing solutions, our automated weighing equipment is designed with hygiene in mind. They are made from naturally hygienic materials and adhere to the highest hygiene standards.

Weighing Up the Options

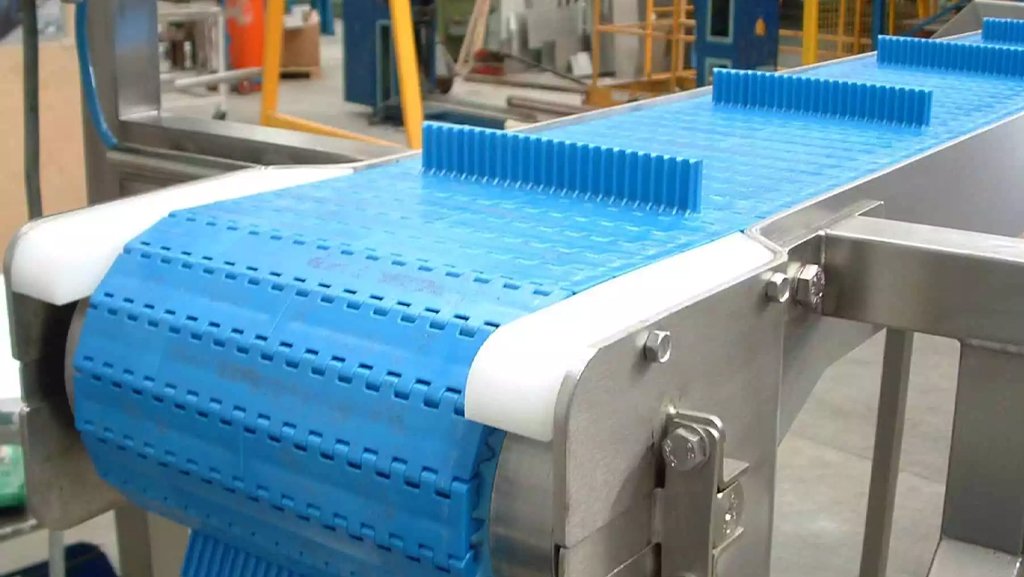

Among the products that we offer are fixed table weigh stations. These semi automated systems allow operators to manually achieve the desired weight whilst the product passes on an adjacent conveyor belt.

A fixed table weighing solution for bakery products is a type of automated system that is specifically designed for use in a bakery setting. This type of system typically consists of a large, fixed table or platform that is equipped with a digital scale.

The scale is used to weigh ingredients, dough, or finished bakery products. The system may also include various other components such as conveyors, hoppers, and dispensers, which are used to move ingredients or products onto the scale and then onto packaging or storage.

Some fixed table weighing solutions also include computerised recipe management systems, which can help to ensure that the correct amount of ingredients are used in each recipe. Additionally, some systems include automated packaging and labeling systems which can help to streamline the packaging and labeling process. These solutions can increase efficiency, accuracy and reduce the labor cost in the bakery.

We also supply checkweighers. These systems allow baked goods to be weighed as they pass along a production line. The system rejects any underweight products based on the specifications set by the customer. These specifications can be easily altered as desired.

Bakery Weighing – Find Out more

There are several benefits of using automated systems for bakery weighing in a bakery setting. Some of these benefits include:

- Increased accuracy: Automated systems can provide more accurate measurements than manual weighing methods, which can help to ensure that the correct amount of ingredients are used in each recipe.

- Increased efficiency: Automated systems can help to speed up the weighing process and reduce the amount of labour required, which can increase overall production efficiency.

- Improved consistency: Automated systems can help to ensure that the same amount of ingredients are used in each batch, which can improve the consistency of finished products.

- Reduced labour costs: Automated systems can help to reduce the need for manual labour, which can lower labour costs and increase profitability.

- Better traceability: Automated systems can help to improve the traceability of ingredients and finished products, which is important for food safety, quality and compliance with regulations.

- Better inventory management: Automated systems can help to track and manage ingredient inventory, which can help to reduce waste and save costs.

- Better customer satisfaction: Automated systems can help to improve the quality and consistency of finished products, which can lead to better customer satisfaction.

Click on the following link if you would like to find out more about Bakery Weighing, or this link for information on other stainless steel equipment manufactured by Wrightfield.