Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

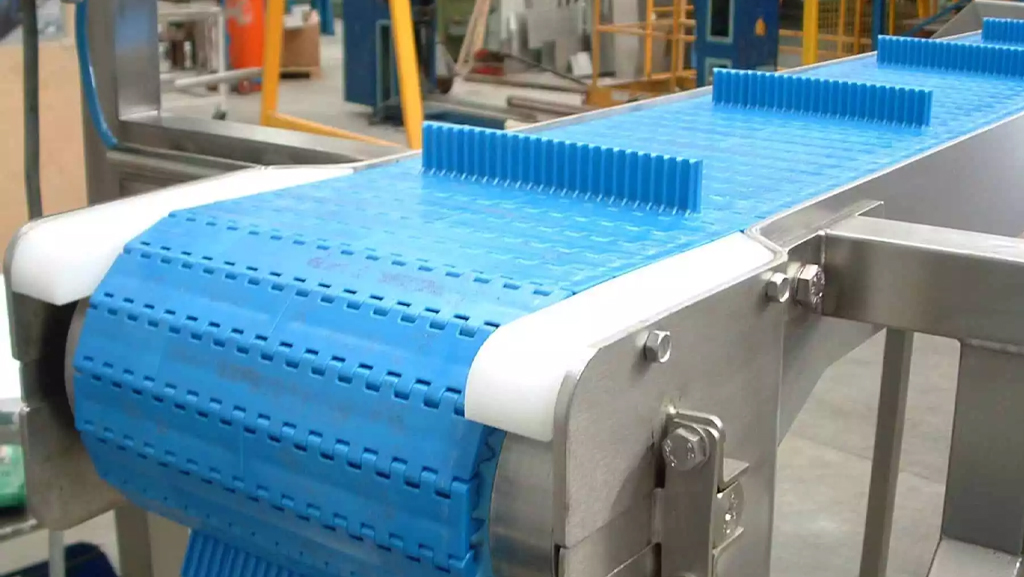

Conveyor maintenance is a critically important part of conveyor belt ownership. This key element helps to ensure reliability and protect longevity. We discuss more in this post, as well as providing some information on maintenance and other after sales services offered by Wrightfield.

Reliability

In the fast paced world of food processing, unplanned downtime can be a very serious issue that results in extremely severe consequences. This is particularly true for any companies in the sector that process livestock or frozen foods. Therefore, when it comes to mechanical equipment, reliability is a key factor.

To ensure reliability is maintained, a company should partake in regular and consistent conveyor maintenance. This will help to ensure that everything with the conveyor is running as it should be and will facilitate reliable service.

Longevity

The cost of purchasing a conveyor belt is often not inconsiderable. However, with regular maintenance a conveyance solution can offer many years of service, helping a company to protect their investment. As well as keeping everything in order, conveyor maintenance can help to highlight small problems that could become bigger issues in the future if left unattended to.

After Sales Care Offered by Wrightfield

At Wrightfield, we offer a professional and responsive after sales service. We provide planned maintenance on a scheduled basis, as well as an emergency maintenance service in the unlikely event that breakdown support is required.

In addition to maintenance and emergency callouts, we also provide a number of other bespoke after sales services. Included in these services are shift cover, such as during busy periods or holidays; spare parts; service contracts; audits and assessments; and remote diagnostics.

Find Out More about Conveyor Maintenance

Click on the following link to find out more about our conveyor systems maintenance or this link for information on other stainless steel equipment manufactured by Wrightfield.

Conveyor Maintenance Tips

- When you purchase a new conveyor system from Wrightfield Conveyor manuals and documentation are typically handed over after commissioning The conveyor systems documents will be extremely important for your maintenance / engineering team to understand how to repair and maintain the conveyor system. Wrightfield also include Spare part numbers and information on how to get replacement parts

- Document all repairs and maintenance you’ve made. Any maintenance performed on conveyor systems should be written in a machine log. This should include noting the cause for the maintenance and the effect. Capturing this information can help you establish a better understanding of what is failing within your conveyor system. It could be beneficial to highlight if the issue is a repeating issue and leaves a note for all staff on how to fix the issues going forward.

- Old conveyor systems can be costly and even sometimes impossible to source parts for. It is important to understand what parts of your conveyor system are obsolete equipment ( before they fail in operation). instead of continuously repairing old, worn out systems it may beneficial in the longer term to replace elements of the conveyor system with a modern, more robust and reliable conveyor. Wrightfield can help companies evaluate the performance and capability of their existing conveyor systems and establish the most effective way for you to conduct conveyor maintenance.