Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

Bakery production equipment is used to produce a wide variety of baked goods, including bread, pastries, cakes, and cookies. Some common types of bakery production equipment include:

- Mixers: These are used to mix ingredients for dough and batter. They come in various sizes and types, such as spiral mixers, planetary mixers, and dough dividers.

- Ovens: These are used to bake the dough or batter. They come in various sizes and types, such as convection ovens, deck ovens, and rotary ovens.

- Proofers: These are used to ferment and proof dough. They come in various sizes and types, such as proofing cabinets and proofing boxes.

- Sheeters: These are used to roll and flatten dough. They come in various sizes and types, such as manual and electric sheeters.

- Moulders: These are used to shape dough into various forms. They come in various sizes and types, such as round and long loaf moulders.

- Dividers: These are used to divide dough into portions of a specific weight. They come in various sizes and types, such as manual and automatic dividers.

- Rollers: These are used to roll dough for pastries, croissants and other baked goods.

- Depositors: These are used to dispense dough or batter into specific shapes and sizes. They come in various sizes and types, such as piston and gravity depositors.

- Cooling racks: These are used to cool down baked goods after they are removed from the oven. They come in various sizes and types, such as wire and tray racks.

- Packaging machines: These are used to package the finished baked goods for sale. They come in various sizes and types, such as flow wrappers, vacuum packagers and tray sealers.

These are just a few examples of bakery production equipment, and the specific equipment used will depend on the type of bakery and the desired end product.

Bakery production equipment is equipment that is used in the product of baked goods. At Wrightfield, we are specialists in the design and manufacture of a range of such equipment, this includes weighing, grading and conveyance solutions.

Built for Bakery

We have more than 20 years of experience in the food processing industry and understand the unique demands and requirements of the bakery sector. We therefore design and manufacture equipment that is finely tuned for use in bakery production.

Our solutions are also tailored to the requirements of a client. This can include a range of factors including the size of their plant, type of product they produce and speed of a conveyor. Our aim is to help our clients to increase efficiency, accuracy and productivity.

Wrightfield bakery production solutions are highly automated, this is a factor that reduces the need for manual interventions. Our solutions are also extremely compatible and can integrate seamlessly into most existing systems.

The Wrightfield moto is Better by Design, a refrain we reference throughout the design and manufacture of a product.

It ensures that we are continually developing our systems: we incorporate the latest technology and employ the most up to date industry best practices. We also use cutting edge manufacturing equipment and techniques.

Wrightfield Bakery Equipment

Our range of bakery equipment includes the following:

Weighing solutions – this includes fixed table weigh stations and checkweighers.

Grading – this includes packaging and labelling machines, as well as equipment that can be used to index both naked and packed products.

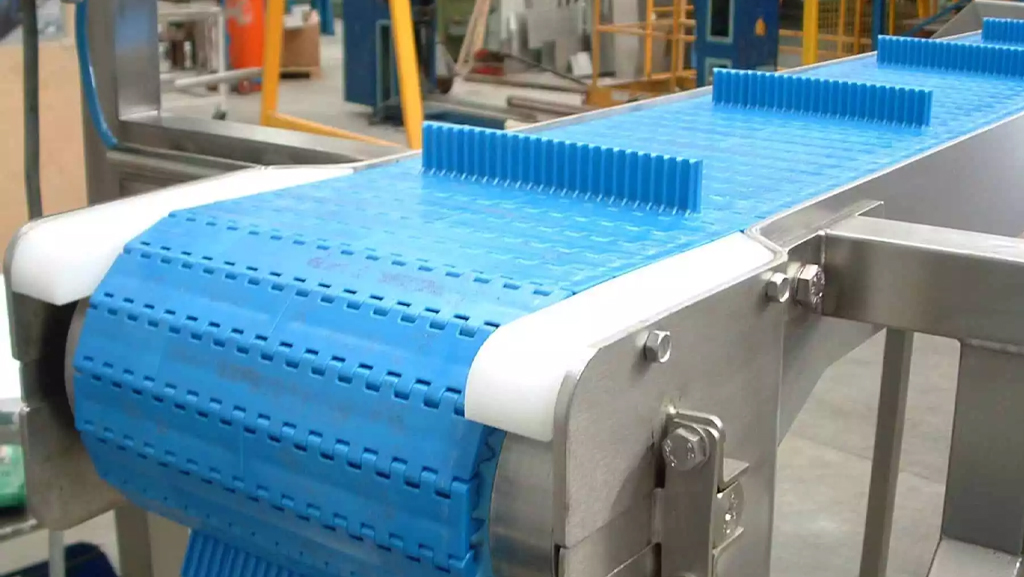

Conveyors and belts – conveyors include spiral conveyors, transfer conveyors, elevators and multi lane & merge conveyors. Meanwhile, our range of belts includes the slat belt, PU belt and modular belt. Additionally, we have the Intralox Activated Roller Belt.

Bakery Production Equipment – Find Out more

Click on the following link if you would like to find out more about equipment for bakery production, or this link for information on other stainless steel equipment manufactured by Wrightfield.