Manufacture of large Chimney Stacks and Cyclones for herb production facility. Project: Camstar Herbs -…

Three main types of conveyor belts

There are three main industrial classes of belt conveyors; food processing conveyors, general material handling and bulk material handling. The conveyor belt system you need will depend on what your transporting, the speed it needs to travel and other factors. We have covered How Conveyor Systems Work in a previous article

Food Processing Conveyors

Whatever format the food product ( raw, chilled, frozen, prepared) enters your production environment cleanliness is crucial for health and safe environment; and your food handling conveyors need to comply to relevant regulations.

Typical applications of a food quality conveyor

- Separating and grading – whereby food items automatically or manually sized and allocated to specific locations

- Reject systems for defects – whereby food product that doesn’t meet grading standards is removed from the production process

- Cleaning of raw fruits, vegetables and salads with water or air

- Transportation from one process to another – i.e. from sizing to coating

- Diverting of frozen or fresh produce

- Drying – whereby an item can dry naturally on the conveyor as it progresses, or be transported through an air dryer

- Transfer of delicate fruit and vegetable products

- Handling of loose and raw food products

- Coding and labeling packaging and bottles

- Conveyor system where hygiene is essential and the conveyor needs to be completely cleaned and sanitised

- Food products that can typically be handled on a food product conveyor include frozen foods, vegetables and fruit, bakery products, fish and seafood, poultry ( including Chicken, Turkey, Goose and Duck), Raw, Fresh, Chilled, Processed product, Ready Meals, Confectionery and Halal

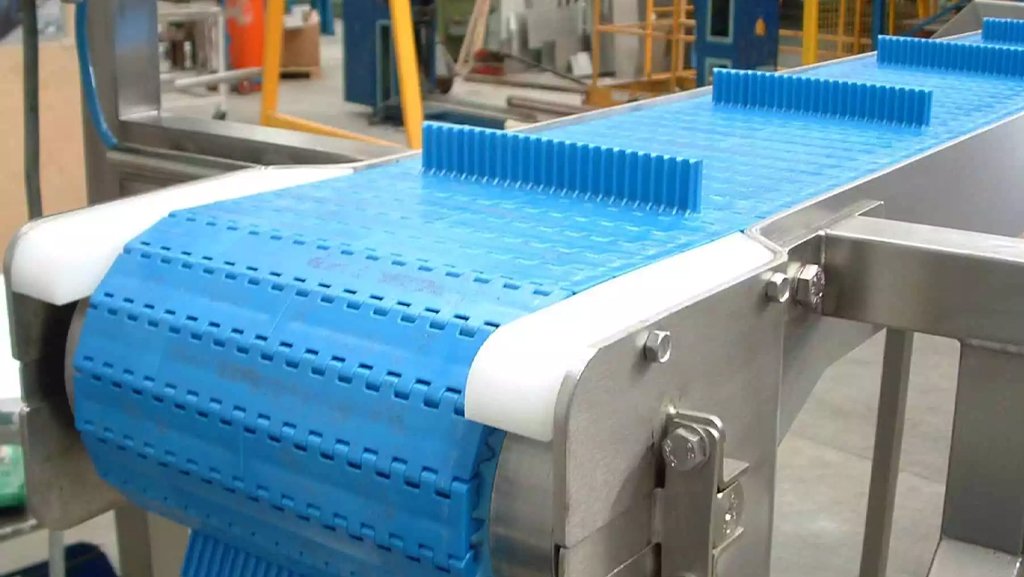

Food Conveyor Grade Belt

There are a wide range of food grade quality belts available with food grade coatings. It is important to ensure that these are fully compliant to FDA and EU regulations.

Typical examples of food grade belting include

- Thermoplastic polyurethane (TPU)

- Thermo drive

- White Belt or Blue food grade Belting

- Antibacterial grade belting

- Abrasion resistant coating

- Blade and knife resistant

- Activated Roller Belt

General material handling belts

These are used to move materials, components, packaging, products, items typically across short distances within the confines of a building. At the end of production they can be used to take from a processing line to a dispatch or transportation area / vehicle.

Bulk material handling belts

As the name suggests bulk material handling belts are used where there are large volumes of dry materials, raw goods, sharp heavy materials, , or metals. Examples of bulk materials are flours, rice, grains, sugar, minerals, ores, sand, stone, and chemicals. For this reason bulk material handling conveyor systems and conveyor belts are useful for industries that produce bulk materials such as food and drink, animal food, agriculture, and chemicals.

Why do people use conveyor belts?

A conveyor systems principle use is to increase / improve throughput on a section of the production or transportation process, by moving products from A to B to C etc in the most efficient and timely manner. The production processing / manufacturing / sorting process is ultimately limited by the production equipment output, so conveyors in and out need to be designed to match input and output speeds. Ultimately conveyors provide a labour cost-saving benefit which means they can get more products manufactured or sorted and sent out to customers in a quicker and more efficient manner.

By reducing the number of people required to carry out the task, conveyor systems usually reduce the space required to move items. This allows the process to run in a smaller area of the facility, freeing up working space.

Free Conveyor System Technical Audit

Get In Touch For Advice And A Quotation

Conveyor Belt Safety

Belt conveyors are the most commonly used power conveyors. They are the least expensive and most versatile being able to carry a variety of shaped objects, small or large, heavy or light, rough random edges or square / flat. Depending on where and how the conveyor system is used impacts on the health and safety measures required. For example, if you’re moving light / compact goods on an incline that goes through multiple processes and sections at high speeds. Then you will have tighter rules and stricter guidelines to ensure the products stay on the conveyor system, compared to the Sushi bar that has small food plates going round on a conveyor belt in a food retailer.

Conveyor Safety Mechanisms

Conveyors used in industrial settings include trip cord safety mechanisms along the sides of the conveyor, with safety start-stop button. This allows operators to shut down the conveyor with immediate effect if a problem arises.

A conveyor system manufacturer who takes health and safety as a paramount feature of their business service will be able to demonstrate their capabilities through their : Track record of customers for whom who they have manufactured conveyor systems / Design and Production facilities / Accreditations such as EN1090-1 , Constructionline, Builders Profile.

What Are The Main Types Of Conveyor Belts – Are you looking for a conveyor system?

What Are The Main Types Of Conveyor Belts, Wrightfield manufacture shuttle conveyor, transfer conveyor, inclined belt conveyors, wire belt conveyor, slat conveyor, roller conveyor, multi lane and merge, spiral conveyor, activated roller belt, modular belt , flexible conveyors, cooling conveyors, metal detection conveyors, quick belt removal conveyors or Thermodrive for example. If you need a conveyor system, for the food industry Wrightfield can help you identify what conveyor system specification would provide you with optimum operating effectiveness and efficiency, increasing throughput and decreasing costs, contact Wrightfield today.

For further information on stainless steel products click here